Over 60 Years of Excellence in Manufacturing

One Source for Precision Machined and Stamped Components

Everything You Need Under One Roof

For over 60 years, Coining has been a leading supplier of machined and metal stamped products for almost every industry, including the Aerospace, Military and Defense, Medical, Telecommunications, Automotive, Semiconductor, and Hermetic Sealing industries.

As a vertically integrated manufacturer, Coining offers Progressive Die Stamping, Blanking, CNC Milling, Turning and Drilling, Automatic and CNC Swiss Machining, Wire EDM, and Polishing Services. All tools, dies, and fixtures are built and manufactured in-house. Coining’s Engineering Team uses the latest software tools: AutoCad, MasterCam, Pro E, Creo, and more.

Products and Applications

Coining's extensive list of products includes battery covers and lids, various types of microelectronic packages, hybrid packages, ceramic packages, sensors, seal headers, caps, connectors pins, solder cups, terminals, and feed-through pins. The world's best Aerospace, Automotive, Defense, Energy, Medical, Military, and Mobile Phone manufacturers use these products to complete their applications regularly.

ISO9001:2015 Registered

Coining maintains a fully equipped quality lab with state-of-the-art measuring and inspecting equipment, including Starrett AVR 300 Vison Systems, Keyence IM-7001 Vision Systems, Keyence VHX Vision Systems, ROIs, OMIS II Vison Systems, Nikon V-12B Comparators, Mitutoyo QM- Measure 353 CMMs, Meiji Microscopes, and Amscope Microscopes, Digital Micrometers, and Digital Calipers.

Specializing in Difficult-to-Machine Materials

Nickel Based Alloys -

Kovar, Alumel, Chromel, Constantan, Inconel 600, Inconel 617, Inconel 625, Inconel 690, Inconel 718, Inconel X-750, Invar, Monel, Nickel 200, Nickel 201, Nickel 230, Hastelloy, Tophet

Stainless Steel Grades -

301, 302, 303, 304, 304L, 309, 316, 316L, 321, 408, 409, 410, 416, 420, 430, 440, 630 (17-4 PH), S155 (15-4PH)

Cold Rolled Steel (CRS) -

1006, 1005, 1008, 1010, 1017, 1018

Copper & Copper Alloys -

C101, C102, C110, C145, C182, C172, C173, C314, C335, C360, C385, C464, C485,

Other Metals & Plastics -

Tantalum, Titanium, Tungsten, Vespel, PPS, FR4.

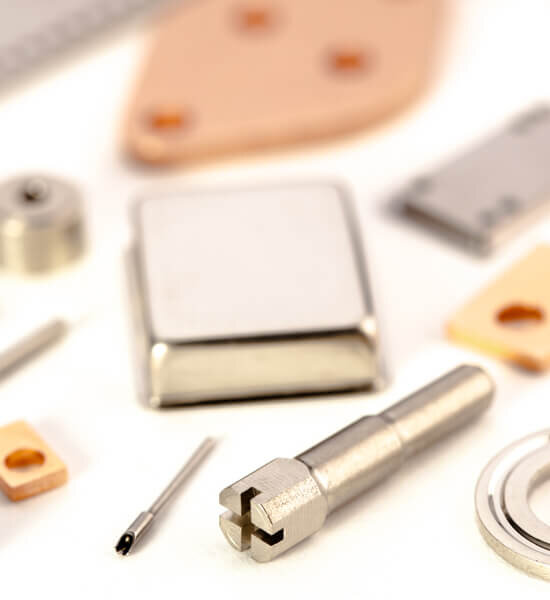

Custom Metal Components

METAL STAMPING & COINING

Coining manufactures custom stamped and coined metal components using single operation and progressive tools and dies. Typically, products are made out of Kovar, Inconel, Chromel, Alumel, Copper, CRS, and Stainless Steel. Coining can routinely hold tolerances as tight as ±.0005″ with their stamping operations.

CNC MACHINING

Coining utilizes 5-Axis CNC milling machines to produce custom housings for the Aerospace, Military & Defense, Telecommunications, Optoelectronics, Semiconductor, and Hermetic Packaging industries. Not only does Coining machine products out of the more common metals, Aluminum and Copper, but they also produce parts out of the hard to machine metals, including Titanium, Kovar, and all Nickel Alloys.

SCREW MACHINE PRODUCTS

Coining uses Swiss Screw Machines to manufacture custom metal components for a broad range of industries, including the Aerospace, Military, Defense, Hermetic Seal, and Medical industries. Typical products include Solder Cup Pins, Thermocouples, Screws, and Implantables, with diameters ranging from 0.2 to 20 millimeters.

WIRE EDM

Coining utilizes Wire EDM machines to manufacture parts that require extremely tight tolerances, commonly ±.0001″. Coining is equipped to handle high-volume EDM projects as well as smaller run jobs. Typical products include fiber optic frames and housings with inside corner radii as sharp as .004″. Coining also uses Wire EDM machines to support their in-house tool and die department.